A raster-scan display processor is a device or component that is used to create images on a computer screen. The process involves scanning the screen from left to right, line by line and then moving down to the next line. The processor activates the necessary pixels as it scans each line to generate the image.

This type of display processor is commonly used in cathode-ray tube (CRT) displays, which were widely used in older computer systems. However, newer display technologies such as liquid crystal displays (LCDs) and organic light-emitting diodes (OLEDs) use different types of display processors.

To operate a raster-scan display processor, the software is used to send image data to the processor in a specific format. The processor then converts the image data into signals that control the electron beam in the CRT or the pixels in an LCD or OLED display.

How Raster-Scan Display Processors Work?

A raster-scan display processor works by generating images on a computer screen through a scanning process. This process involves scanning the screen line by line, from left to right and top to bottom, and activating the necessary pixels to create an image.

To operate a raster-scan display processor, image data is sent to the processor in a specific format using the software. The processor then converts this data into signals that control the electron beam in the cathode-ray tube (CRT) or the pixels in modern display technology such as a liquid crystal display (LCD) or an organic light-emitting diode (OLED) display.

The scanning process of a raster-scan display processor begins at the top left corner of the screen and moves across each line, activating the appropriate pixels as it goes. The processor then moves down to the next line and repeats the process until the entire screen has been scanned. The speed at which the scanning process occurs is determined by the refresh rate of the display.

In a CRT display, the electron beam is directed toward the screen, causing the phosphor on the screen to glow in a specific color. By controlling the intensity and position of the electron beam, the raster-scan display processor is able to activate the necessary pixels to create an image.

In modern display technology such as an LCD or an OLED display, the pixels are controlled directly by the processor using an array of transistors. The processor activates the appropriate transistors to control the intensity and color of each pixel, creating the desired image.

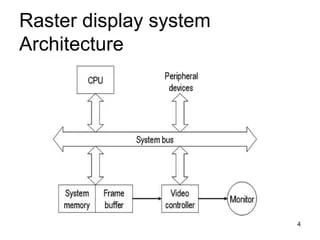

Raster-Scan Display Processor structure

A raster-scan display processor is a type of graphics processing unit (GPU) that is responsible for generating the video signals that create the images on a computer monitor. The structure of a raster-scan display processor typically consists of several key components:

- Video Memory The video memory is used to store the image data that is being displayed on the screen. This memory is typically organized into a grid of memory cells, with each cell corresponding to a single pixel on the screen.

- Address Generator The address generator is responsible for generating the memory addresses that are used to access the video memory. This is typically done in a sequential manner, with the address generator stepping through each row of pixels on the screen.

- Timing Generator The timing generator is responsible for generating the synchronization signals that are used to ensure that the image is displayed correctly on the screen. This includes signals that synchronize the horizontal and vertical scanning, as well as signals that control the timing of the pixel data being sent to the monitor.

- Digital-to-Analog Converter (DAC) The digital-to-analog converter is used to convert the digital image data stored in the video memory into the analog signals that are required by the monitor. This involves converting the binary data stored in the memory into a series of voltage levels that correspond to the intensity of the light emitted by the monitor’s phosphors.

- Output Amplifier The output amplifier is used to boost the strength of the analog signals generated by the DAC so that they can be transmitted to the monitor over a distance.

Evolution of Display Technology

Display technology has come a long way since its inception. From the early days of cathode ray tubes (CRTs) to modern OLED and QLED displays, the evolution of display technology has been remarkable. Let’s take a look at some of the major milestones in the evolution of display technology.

Cathode Ray Tube (CRT)

The CRT display was the first commercially successful electronic display technology. It used a vacuum tube to produce an image on a phosphorescent screen. CRT displays were bulky, heavy, and had a low resolution. They were commonly used in televisions and computer monitors until the late 1990s.

Liquid Crystal Display (LCD)

The LCD display was a major breakthrough in display technology. It replaced the bulky CRT displays with a slim, lightweight, and energy-efficient display. LCD displays are commonly used in modern televisions, computer monitors, and smartphones. They offer high resolution and a wide range of colors.

Plasma Display Panel (PDP)

The PDP display was introduced in the 1990s. It used small cells containing plasma to create an image. PDP displays were popular for their large screen sizes and high contrast ratios. However, they were bulky and energy inefficient, which led to their decline in popularity.

Organic Light Emitting Diode (OLED)

The OLED display is a newer technology that has gained popularity in recent years. It uses organic compounds to create a self-illuminating display that doesn’t require a backlight. OLED displays offer high contrast ratios, deep blacks, and a wide range of colors. They are commonly used in high-end televisions and smartphones.

Quantum Dot Light Emitting Diode (QLED)

The QLED display is a newer technology that uses quantum dots to create a vibrant, high-quality display. QLED displays offer a wider color gamut than traditional LCD displays and are more energy-efficient than OLED displays. They are commonly used in high-end televisions.

Advantages of using a raster-scan display processor

There are several advantages to using a raster-scan display processor in computer systems:

- Simple and efficient: Raster-scan display processors are relatively simple and efficient, making them a cost-effective option for generating images on computer screens.

- High resolution: Raster-scan display processors can generate high-resolution images because they scan the screen one pixel at a time.

- Smooth image display: The raster-scan display processor can display images smoothly because it scans each line in sequence, ensuring that all pixels are activated in the correct order.

- Easy to use: Raster-scan display processors are easy to use and require minimal programming or configuration.

- Compatible with older systems: Since raster-scan display processors were commonly used in older computer systems, they are compatible with legacy hardware and software.

Disadvantages of using a raster-scan display processor

While there are several advantages to using a raster-scan display processor, there are also some disadvantages to consider:

- Limited color depth: Raster-scan display processors are typically limited in their color depth, which can result in color banding and less accurate color representation.

- Slow refresh rate: Raster-scan display processors can be slow in refreshing the screen, which can result in flickering and screen tearing.

- Not suitable for high-speed graphics: Due to their scanning process, raster-scan display processors are not suitable for high-speed graphics, such as video playback and gaming.

- Limited viewing angles: Cathode-ray tube (CRT) displays, which commonly use raster-scan display processors, have limited viewing angles compared to modern display technologies like LCDs and OLEDs.

- Bulky and heavy: CRT displays can be bulky and heavy, which makes them less portable and more difficult to move or transport.

Challenges in Reusing Old CRT Displays

Old CRT displays, which were once the standard display technology, are now obsolete due to the advent of newer and better display technologies such as LCD, LED, and OLED. While many people have upgraded to newer displays, there are still many old CRT displays that are sitting unused. Reusing these old displays presents a number of challenges.

- Bulky and Heavy One of the main challenges with reusing old CRT displays is their bulkiness and weight. CRT displays are bulky and heavy, making them difficult to move and store. This can be a challenge for people who want to repurpose them for use in a home or office.

- Low-Resolution CRT displays have a low resolution compared to modern displays, which can make them unsuitable for certain tasks such as video editing, gaming, or graphic design. They also have limited color reproduction and are prone to screen flickering, which can cause eye strain.

- Energy Inefficiency CRT displays consume a lot of energy compared to modern displays, which are much more energy-efficient. This can result in higher energy bills and a greater environmental impact.

- Obsolete Technology CRT displays are now considered outdated technology, and as a result, they may not be compatible with newer computer hardware and software. This can make it difficult to connect them to modern computers or use them for certain tasks.

- Disposal Challenges Finally, when it comes time to dispose of old CRT displays, there are additional challenges. These displays contain hazardous materials such as lead and phosphor, which can be harmful to the environment if not disposed of properly. Disposing of these materials requires special handling and may not be possible in some areas.

Applications of Raster-Scan Display Processors

Raster-scan display processors have been widely used in various applications, including:

- Computer graphics: Raster-scan display processors have been used in computer graphics since the early days of computer systems. They are commonly used to generate static images, such as icons, logos, and user interfaces.

- CAD/CAM: Raster-scan display processors have also been used in computer-aided design and computer-aided manufacturing (CAD/CAM) applications. They are used to display complex 2D and 3D models and allow designers and engineers to manipulate the models in real time.

- Medical imaging: Raster-scan display processors are also used in medical imaging applications, such as X-ray and MRI machines. They are used to display the images generated by these machines and allow medical professionals to analyze and diagnose medical conditions.

- Video editing: Raster-scan display processors are used in video editing applications to display video footage in real time. They allow editors to manipulate video content and preview the changes in real time.

- Gaming: While raster-scan display processors are not well-suited for high-speed graphics, they have been used in older gaming systems, such as arcade machines and early home consoles.

The Future of Raster-Scan Display Processors

The future of raster-scan display processors is limited, as modern display technologies have largely replaced them in most applications. However, there are still some niche applications where raster-scan display processors may continue to be used, such as in the restoration of old video game consoles and arcade machines.

In these applications, raster-scan display processors are preferred because they can accurately replicate the look and feel of older display technologies, such as CRT displays. The limitations of raster-scan display processors, such as their limited color depth and slow refresh rates, are not significant drawbacks in these applications, as they are part of the desired aesthetic.

1 thought on “Raster-Scan Display Processor”